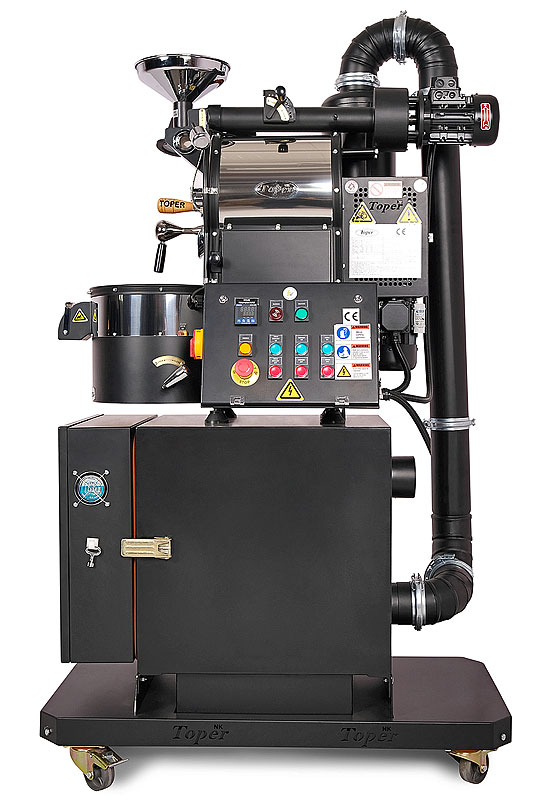

Electrothermal afterburner for Cafemino® Electric

Electrothermal afterburner is the latest innovation and complete solution to roast with Cafemino® Electric without any venting; anywhere, anytime.

Great advantages of electrothermal afterburner are:

- No need for venting

- No permits or contractors are needed

- Very low installation cost

- No construction work required

- No smoke emitted

- Power consumption is lower than classic afterburners

- Low and easy maintenance

- Can be connected to previous models of Cafemino® Electric

- Secondary Pipes carry products of combustion (smoke, micro particles, exhaust gasses, etc.) from Cafemino® to electrothermal afterburner.

- Main Power Button is the main power switch of the unit

- Emergency Button shuts down the equipment in the case of an emergency

- Control Panel is equipped with start and stop switches, an a digital temperature controller controlling the afterburner’s heater operation

- Electrothermal Resevoir is the chamber where unwanted products of combustion are collected and conditioned

- Conditioned and completely clean air runs out from the Clean Air Outlet

- Control Panel Fan cools down the electrical circuit elements of the control panel

- Heavy Duty Rolling Cart is equipped with safety brackets to secure the whole unit while transferring in the facility.

Standard features

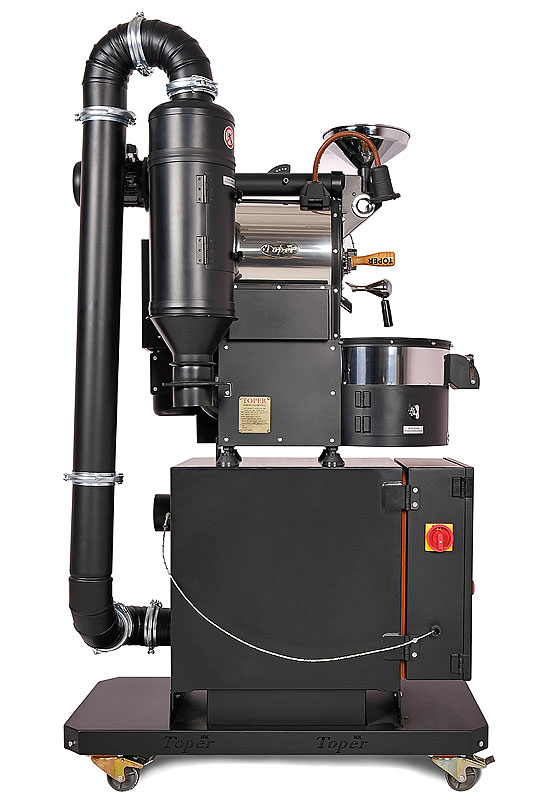

- Secondary pipes run exhaust gasses, smoke and other micro particles directly from the top of the chaff collector cyclone to electrothermal afterburner

- All the combustion products are conditioned in the afterburner by electrothermal method

- Cafemino® Electric can be run indoors without any venting equipmentif equipped with electrothermal afterburner

- Special brackets fix Cafemino® roaster on top of the electrothermal unit for completely secure and vibration-free operation

- Electrothermal afterburner is very easy to operate and clean